AION - The World's largest Rolling Ball Clock

Aion, the marble run clock at Bucherer's flagship store in Lucerne was built by Sinnwerkstatt GmbH (CH) and Markinetic (NL) on behalf of Creative Circle (CH)

At the heart of the marble run is a

large clock, which is based and operates on kinetic

principles. At the watch's periphery, rolling glass

marbles – which are constantly in motion –

indicate the seconds, minutes, quarters and hours in an

impressive spectacle involving time. Driven by kinetic

energy, the crystal spheres find their way through the

rollercoaster at high speed, seeking the gigantic minute

ring. One marble ends up in the ring every minute, until

60 of them finally make up an hour. A polar opposite to

this ongoing motion is provided by a giant crystal ball

on the ground floor, which oscillates once every quarter

of an hour. The mechanical components, all perfectly

geared to one another, are fascinatingly combined to

create a clock system that is precise, completely

self-contained and infinite. And this is where the work

takes its name: Aion. The word comes from ancient Greek

philosophy and stands for the infinity of time. And this

is where the work takes its name: Aion. The word comes

from ancient Greek philosophy and stands for the infinity

of time.

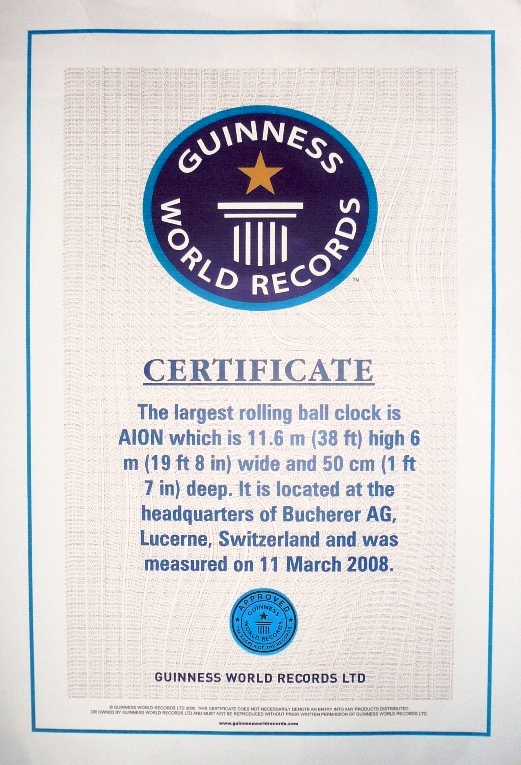

World's largest marble run clock

The installation extends

to all four floors in the Bucherer store, is 11.6 m (38

ft) high and 6 m (almost 20 ft) wide. In the entire

system, 150 crystal balls measuring 30, 40 and 150 mm

(1.2, 1.6 and 5.9 in) run along 297.8 m (977 ft) of

track. These impressive dimensions have qualified for

official recognition by the Guinness Book of World

Records as the longest marble run clock in the world.

Precision craftsmanship all down the line

The project was entrusted

to Hanns-Martin Wagner from Switzerland and Mark Bischof

from Netherlands. Work on the sculpture began in spring

2006 with a series of detailed feasibility studies, and

the project was finally completed after 12 months. All

the elements and components used for the iconic structure

are unique and were painstakingly made by hand.

The project team

Up to 12 people and lots

of subcontractors got involved with the project:

Mark Bischof, Amsterdam (NL): Creative design,

drawings, metal working

Lukas Bischofberger, Rikon (CH): Metal working,

mechanics

Claudia Brenner, Basel (CH): Accounting

Sonja Greuter, Zürich (CH): Metal working,

polishing

Lorenz Grimmer, Dinhard (CH): Workshop

supervisor, engineering, metal working, toolmaking,

mechanics, assembling

Stefan Grünenfelder, Breno (CH): Assembling

Roman Hutter, Sogamoso Boyaca (CO): Sculptor

Julie Lagger, Rikon (CH): Polishing

Martin Märki, Winterthur (CH): Engineering,

electronic controlling, programming, assembling

Stefan Schwab, Stuttgart (DE): Technical

drawings and layout

Hanns-Martin Wagner, Wendlingen a.N. (DE) und

Langnau a.A. (CH): Project management, technical

drawings, metal working, assembling

Jonas à Wengen, Winterthur (CH): Metal working,

polishing